Manufacturing Output Fluctuations During Economic Cycles

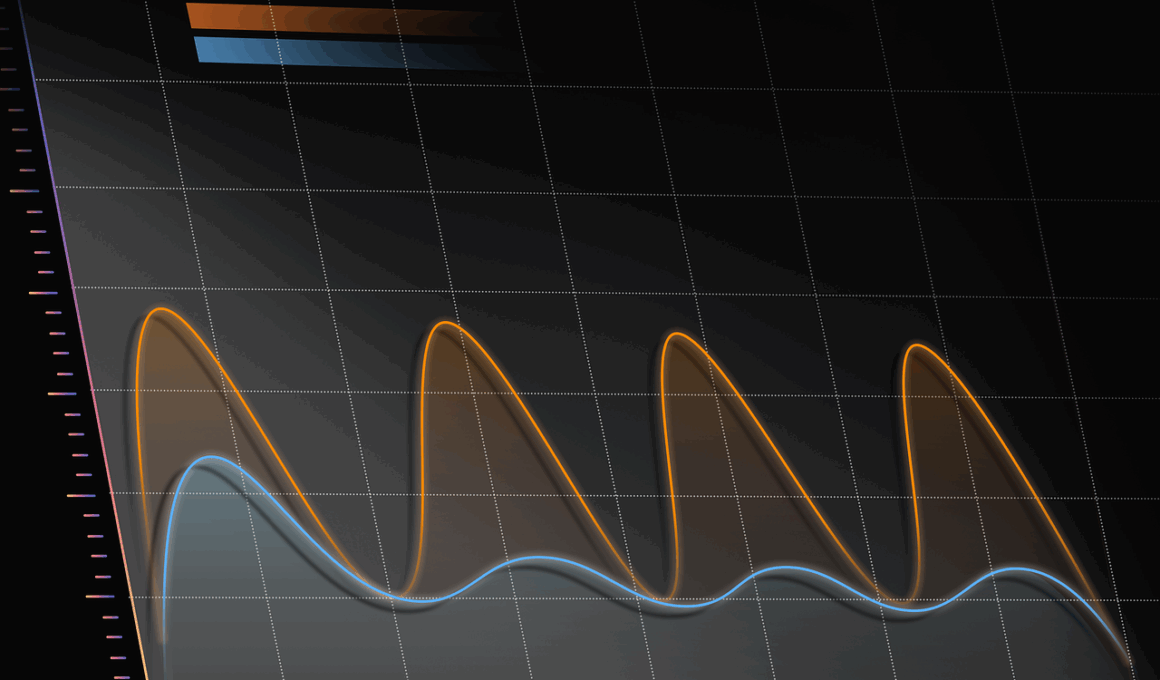

Manufacturing output is a critical component of economic indicators, representing the production capacity and efficiency of industries. These fluctuations are often closely linked to economic cycles, experiencing significant changes during periods of expansion and recession. The manufacturing sector reacts to shifts in consumer demand, which directly influences output levels and employment rates. Changes in fiscal and monetary policies can also have substantial impacts on manufacturing. For instance, low-interest rates usually stimulate borrowing, leading to increased production. Conversely, during downturns, manufacturers may scale back operations in anticipation of reduced demand. Various factors contribute to these cycles, including international trade dynamics and technological advancements affecting productivity. Moreover, psychological aspects, such as consumer confidence, play a vital role in shaping manufacturing output. When consumers feel optimistic, they tend to spend more, thus prompting manufacturers to increase their output. The correlation between manufacturing output and economic indicators is evident, making it essential to monitor these fluctuations closely. Understanding these patterns can help businesses and policymakers make informed decisions that promote stability and growth in the economy.

Analyzing the historical data of manufacturing output reveals distinct trends during different economic cycles. In periods of economic growth, manufacturing output typically rises as businesses invest in infrastructure and technology. This creates an environment of increased production capacity and innovation. Conversely, during recessions, manufacturing output often declines sharply. This leads to a notable decrease in jobs and income for many workers in the sector. The Global Recession of 2008 serves as a clear example, where manufacturing output plummeted drastically as demand shrank. The recovery was slow as consumers regained their confidence, businesses resumed investing, and overall production increased gradually. Such cyclical patterns emphasize the need for adaptive strategies within manufacturing industries, including flexible production capabilities and diversification of product lines. Furthermore, international competition poses additional challenges that can influence manufacturing output significantly. Manufacturers need to stay agile to respond to changing global market demands and shifts in trade policies. As markets become increasingly interconnected, understanding these economic cycles is crucial for strategic planning and resource allocation. By leveraging historical data, businesses can position themselves optimally within their respective markets to navigate these economic fluctuations effectively.

The Impact of External Factors on Manufacturing

External factors play a significant role in influencing manufacturing output fluctuations. Global events such as pandemics, geopolitical tensions, and natural disasters can disrupt supply chains, leading to unexpected changes in output levels. For instance, the COVID-19 pandemic highlighted vulnerabilities within global supply chains, resulting in production halts and delays. Manufacturers were forced to adapt rapidly, often seeking local suppliers or alternative materials to sustain operations. Additionally, fluctuations in raw material prices can significantly impact manufacturing output. When prices rise, manufacturers may reduce production costs by lowering output, which can further influence employment rates. Moreover, currency exchange rates are critical as they affect the price competitiveness of exports. A weaker domestic currency can boost exports, increasing manufacturing output, while a stronger currency can have the opposite effect. Consequently, understanding these external influences is essential for assessing manufacturing performance. Policies aimed at stabilizing these external factors can help mitigate their adverse effects on manufacturing sectors. In summary, manufacturers need to remain vigilant about external factors to navigate the intricacies of economic indicators effectively to optimize their output.

Technological advancements have fundamentally transformed the manufacturing landscape, leading to significant fluctuations in output. Automation, artificial intelligence, and data analytics have introduced efficiencies previously unattainable. With the advent of smart manufacturing, companies can now optimize production processes in real-time, enhancing output while reducing costs. However, these changes also pose challenges, including workforce displacement and the need for upskilling. Many manufacturers are navigating this shift by investing in workforce training programs that prepare employees for new roles in automated environments. This transition is essential to maintain a competitive edge in an increasingly technology-driven landscape. Advanced manufacturing technologies enable firms to respond more flexibly to market demands, allowing for greater customization and efficiency. The integration of IoT (Internet of Things) devices also provides manufacturers with valuable insights into their operations, further enhancing output levels and decision-making processes. As these technologies evolve, their impact on manufacturing output will continue to shape economic cycles. Therefore, staying abreast of technological trends is crucial for manufacturers aiming to harness the potential benefits while mitigating risks associated with such transitions.

Government Policies and Manufacturing Output

Government policies, including fiscal incentives and regulations, have a profound effect on manufacturing output fluctuations. Tax incentives for production, research, and development can encourage manufacturers to expand their operations and invest in new technologies. Such policies aim to stimulate growth within the sector, leading to increased output and job creation. Conversely, stringent regulations can hinder manufacturing output, particularly if compliance costs are high or if regulations stifle innovation. Manufacturers often respond to regulatory environments by adjusting their production strategies, which can lead to fluctuations in output levels. Moreover, trade policies, such as tariffs and import/export regulations, can directly impact manufacturing by altering competitive landscapes. Tariffs on imported goods can make domestic products more appealing, increasing local manufacturing output. However, retaliatory tariffs can also lead to reduced demand for exports, negatively affecting output. Policymakers must strike a delicate balance when crafting legislation that supports growth while ensuring fair competition. By understanding the implications of various policies, manufacturers can better navigate these changes and maintain consistent output levels throughout different economic cycles.

Consumer demand is often the main driver of manufacturing output, exhibiting clear fluctuations in response to economic cycles. When consumers feel secure in their financial situations, they tend to spend more, prompting manufacturers to increase their production levels. This phenomenon is especially noticeable during periods of economic expansion when rising incomes lead to greater consumption of goods. On the other hand, during economic downturns, consumer confidence typically declines, resulting in decreased spending and lower manufacturing output. Businesses need to accurately predict these shifts in consumer demand and adjust their production schedules accordingly. Utilizing market research and consumer data can empower manufacturers to make informed decisions that align output with market needs. Additionally, seasonal trends can also affect manufacturing output. Some industries experience predictable fluctuations during specific times of the year, such as the retail manufacturing sector during holidays. These seasonal patterns necessitate tactical planning to optimize production and inventory management. Engaging in demand forecasting allows manufacturers to proactively manage operations based on anticipated consumer behavior. Hence, recognizing the relationship between consumer demand and manufacturing output is essential for maximizing productivity.

Future Trends in Manufacturing Output

Looking ahead, several trends are shaping the future of manufacturing output within economic cycles. Sustainability is becoming a critical focus as consumers grow increasingly aware of environmental impacts. Manufacturers are implementing greener production processes, which can lead to increased initial costs but ultimately contribute to long-term savings and enhanced brand loyalty. Additionally, the shift toward circular economies is pushing manufacturers to rethink their approaches by focusing on recycling and reusing materials. Such methods can lead to innovative products and potentially higher output levels. Furthermore, digital transformation is set to redefine manufacturing with the incorporation of advanced technologies like AI and robotics. These innovations facilitate better data analysis and operational efficiencies, enabling manufacturers to align output more closely with real-time market demands. Predictive analytics, for instance, allows for smarter inventory management, reducing waste and improving responsiveness. Finally, geopolitical factors will continue to influence global manufacturing trends, affecting output levels through trade agreements and tariffs. By embracing these future trends, manufacturers can position themselves strategically to navigate the complexities of economic cycles and enhance their output in an evolving landscape.

In conclusion, understanding the intricate relationships between manufacturing output and economic cycles is vital for businesses and policymakers alike. Monitoring fluctuations in manufacturing output provides key insights into the overall health of the economy. Various factors—including consumer demand, technological advancements, and government policies—play crucial roles in shaping these fluctuations. By analyzing historical data and recognizing current trends, stakeholders can anticipate changes and devise strategies to navigate uncertainties effectively. As the manufacturing landscape continues to evolve, integrating sustainability and digital transformation will be essential in maintaining competitiveness and resilience. Moreover, being mindful of global events—such as geopolitical tensions and pandemics—will aid manufacturers in adapting swiftly to disruptions that may impact output. In navigating these challenges, investing in workforce development and advanced technology will be paramount in enhancing productivity. The ability to respond to fluctuations in manufacturing output will ultimately determine the success and sustainability of many industries. Thus, staying informed and adaptable in the face of economic cycles is crucial for the future of manufacturing output, ensuring alignment with the ever-changing demands of the global market.